The venue of the stage lighting road hanging construction of the four major safety protection measures

1 edge anti drop system

The construction of the road in the road is usually carried out in high altitude, according to the location of different suspension beams, construction workers often have to climb out of the road to climb the roof truss on the construction. Therefore, it is very important to follow safety regulations and adopt reliable and appropriate safety protection facilities. In the United States, "Occupational Safety and Health Standards" (OSHA standard) clearly stipulates: in any edge without protection (horizontal or vertical surface) walking or work, when the height and the height of the surface than the ground higher than 1.8 m , It should be used edge anti-drop system.

The edge drop protection system generally includes handrails, safety net systems or personal fall rescue systems. The OSHA standard also requires employers to provide training courses for each employee who is likely to be injured in an exposed environment. Following this course, the employee can minimize the damage to each employee after the fall.

2 fall protection system

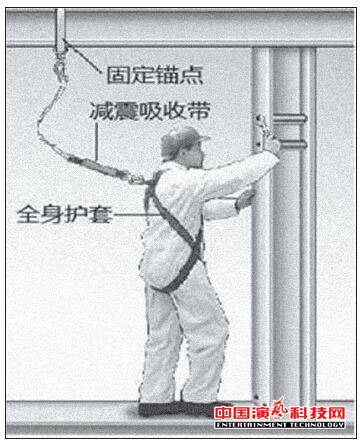

Fall protection system can also be divided into active protection and passive protection. Active fall protection generally refers to the use of safety protection to protect those who have to pass through some of the possible fall area of the staff, the security protection by the protection of the entire body of the cable sets and damping tie, as shown in Figure 6. Passive fall protection is protected by a number of other devices that do not require physical contact with workers, including protective fence, fall arrest, hole cover, ladder guard cage, and so on.

Figure 6 Schematic diagram of the security zone

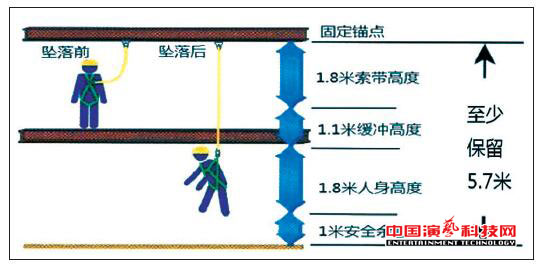

In the case of active fall protection, the connection of the safety cuff to the body requires a reasonable chooseion of the anchor of the safety cuff. In order to ensure safe and reliable, when using a 1.8 m long shock absorber cable, the cable with a fixed point to any impact on the fall of the obstacle between the net distance to be 5.7 m, the specific calculation process is as follows:

(1) First, assume that the average height of the workers is 1.8 m, the use of a set of 1.8 m damping belt and body protection lasso need to consider increasing the cushioning distance of the shock absorber 1.1 m;

(2) Then, there may be lasers do not fit, the worker height is greater than the average height or calculation error, then consider increasing the safety distance of 1 m;

(3) Finally, the cable length, buffer height, height and safety margin added, the entire height of 5.7 m, is recommended to set aside the safe fall distance, as shown in Figure 7.

Figure 7 Schematic diagram of the potential drop height

In this way, even if the anchorage cable at the top of the anchor fixed position is relatively low, you can drop the height of the risk is not enough to minimize the risk. When workers are in a dangerous environment, they need to use anti-fall systems from beginning to end.

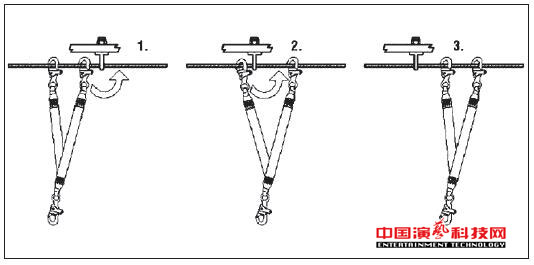

3 Y-type sling

The use of Y-type sling also ensures the safety of the workers, Y-type cable hanging hook connection shown in Figure 8. In the use of Y-type sling in the process, at least one of the two padlocks must be connected with the life-saving system, can also be based on the specific work of the scene, and the suspension beam or reliable road safety railings connected, as shown in Figure 9 Show.

Figure 8 Y-type cable hanging hook connection diagram

Figure 9 workers in the actual construction of the safety protection measures

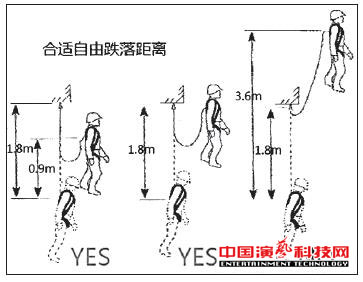

4 suitable free fall distance

In order to avoid free fall above 1.8 m, the height of the lasso and body joints shall not exceed the fixed anchor of the lasso, as shown in Fig. The purpose of this operation is to ensure that in the fall occurs, the protection of the construction workers and the protection zone can be a smaller impact. Properly shortening the lasso protection sling without affecting the construction can also help to reduce the impact due to gravity.

Figure 10 A suitable free fall distance diagram

In order to ensure the safety of personnel, the safety of the venue structure and the smooth holding of activities, the activities of the equipment in the hanging point map need to be pre-rigorously reviewed. First of all, the person in charge of the venue will usually provide the activities of the construction side of the road to the suspension of the hanging beam requirements, that is, the maximum allowable load in the region and the maximum load of a single suspension beam, and the scale of the track Hanging beam CAD drawings. Second, the choreographers in accordance with the suspension beam can be hanging position, the activities of the hanging point map and roof frame hanging beam diagram combination. Some points are usually not exactly below the hanging beam, so after the appropriate adjustment to complete the final hanging point map. Finally, those who are familiar with the suspension structure of the roof truss structure need to mark the representative parts of the hanging chart near the load limit, requiring the designer to modify the lifting point and disperse the force. If the performance of the load exceeds the engineering requirements of the hanging requirements, hanging point reviewers have to commission the roof design side to recalculate the hanging load distribution, and clearly indicate how to improve these loads, accordingly, the building side must strictly abide by and in Site implementation.

The requirements of the road hanging should be concise, easy to be linked to the construction of personnel to understand and properly use. In the process of hanging construction, but also need to follow up the scene of specialized personnel, any part of the hanging structure is strictly prohibited overload phenomenon, prohibit the area without engineering guidelines for free hanging.